Softgel Elasticity Testing Machine

Gelatin capsules are one of the most popular types of oral medication delivery systems. They are used for encapsulating liquid or semi-liquid substances, including vitamins, minerals, and pharmaceuticals, providing a protective shell that safeguards the contents from environmental factors. To ensure the quality and safety of gelatin capsules, it is crucial to assess their strength and elasticity.

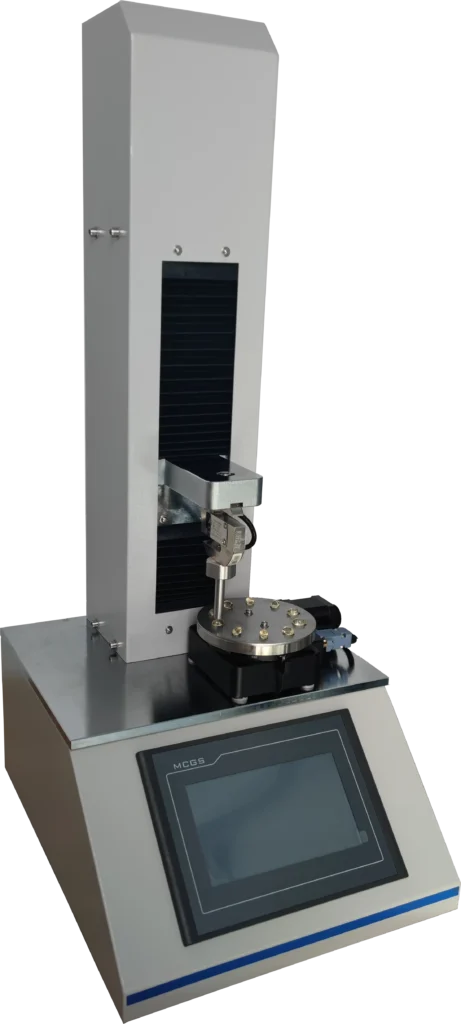

The Softgel Elasticity Testing Machine is a critical tool for pharmaceutical and nutraceutical manufacturers to evaluate the structural integrity and performance of softgel capsules. This machine is designed to simulate real-world conditions, providing accurate data on the capsule’s ability to withstand forces during handling, transportation, and storage. By performing both penetration and compression tests, the machine offers a comprehensive assessment of the capsule’s mechanical properties.

What is the Softgel Elasticity Testing Machine?

The Softgel Elasticity Testing Machine is a sophisticated instrument designed to assess the mechanical properties of gelatin capsules, including their hardness, elasticity, and seal strength. This machine conducts a variety of tests to determine the force required to rupture the capsule’s wall, its resistance to deformation under compressive load, and the strength of the capsule seal.

The testing machine uses a penetration or compression method with a 10mm-diameter probe, which applies a controlled force to the capsule’s surface. The test simulates real-world stress scenarios, helping manufacturers identify weaknesses in the gelatin film or seal that could compromise the capsule during packaging and transportation. The data gathered from these tests ensures that the capsules meet the required quality standards for strength and durability.

Softgel Elasticity Testing: Measuring Wall Deformation and Strength

Softgel elasticity testing is a critical feature of the Softgel Elasticity Testing Machine. It evaluates how much the capsule’s wall can deform under a specific compressive load before it loses its structural integrity. This elasticity measurement is crucial for understanding the softgel capsule’s behavior under varying pressure conditions.

The machine applies a precise compressive force and measures the resulting deformation. This allows manufacturers to ensure that their softgel capsules are both flexible enough to endure handling and transport, yet strong enough to prevent rupture during use. Testing the elasticity also helps identify any weaknesses in the material, ensuring that the softgel maintains its form and function throughout its lifecycle.

What is Softgel Capsule Made Of?

Softgel capsules are typically made from gelatin, a substance derived from animal collagen, and are commonly used to encase liquid or semi-liquid contents such as oils, extracts, or suspensions. However, there are also vegan alternatives to gelatin, made from plant-based materials such as agar or hydroxypropyl methylcellulose (HPMC). These capsules provide a protective barrier, preserving the active ingredients and enhancing bioavailability.

The Softgel Elasticity Testing Machine helps ensure that these capsules—whether made from traditional gelatin or plant-based alternatives—meet the necessary strength and elasticity standards for optimal performance. By evaluating the physical properties of the capsule wall, the machine provides valuable insights into how the capsule will behave under real-world conditions.

Functions and Benefits of the Softgel Elasticity Testing Machine

The Softgel Elasticity Testing Machine comes equipped with several advanced testing functions that allow for a comprehensive evaluation of softgel capsules:

- Force Measurement: The machine allows users to set a specific force value and records the distance the probe travels until the set force is reached.

- Peak Force Measurement: This feature captures the maximum force exerted during the rupture test, providing insight into the capsule’s resistance to breaking.

- Distance Measurement: The machine also measures the force at a particular distance, allowing for detailed analysis of the capsule’s behavior under compression.

Benefits:

- Comprehensive Testing: Multiple test programs enable a complete analysis of the capsule’s mechanical properties.

- Increased Test Efficiency: A rotating table increases throughput, allowing multiple tests to be completed quickly.

- Time-Saving Automation: Automatic statistical functions save time and streamline the testing process.

- Durable and Reliable: The machine is built for long-lasting service, ensuring accurate results over an extended period.

Technical Features and Customization Options

The Softgel Elasticity Testing Machine boasts several technical features that enhance its accuracy and usability:

- PLC Control Unit and HMI Touch Screen: The machine is equipped with a user-friendly 7-inch touch screen for easy operation and control.

- Precision Ball Screw and Stepper Motor: These components ensure accurate and smooth operation for reliable test results.

- Variable Test Speed: The machine supports a range of test speeds, which can be adjusted to suit different testing requirements.

- Customizable Fixtures: The machine offers a variety of fixtures to accommodate different capsule sizes and test conditions.

- Safety Features: The system includes a position restrictor and overload protection to prevent damage to the machine or capsules during testing.

- Automatic Return Function: After each test, the machine automatically returns to its starting position, saving time and ensuring smooth transitions between tests.

- Output Options: Results are displayed on the screen and can also be printed via a dot-matrix microprinter. Additionally, RS232 output is available for integration with other systems.

Main Parameters

Main Parameter – Softgel Elasticity Testing Machine

Applications of the Softgel Elasticity Testing Machine

The Softgel Elasticity Testing Machine is invaluable for industries such as pharmaceuticals, nutraceuticals, and food production, where gelatin capsules are widely used. Manufacturers in these industries rely on the machine to ensure their products meet the necessary quality and safety standards. The machine helps verify that the capsules will perform well under conditions such as pressure, temperature fluctuations, and mechanical stress.

Why Choose the Softgel Elasticity Testing Machine?

The Softgel Elasticity Testing Machine offers a precise, reliable, and efficient solution for testing the strength and elasticity of softgel capsules. By accurately simulating real-world conditions, the machine ensures that softgel capsules are durable and safe for consumer use. With customizable settings and user-friendly controls, this machine is an essential tool for quality control in any manufacturing process involving softgel capsules.